1943 MB Horn Repair

5/3/2012

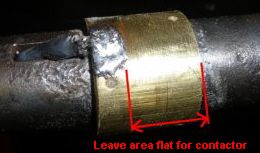

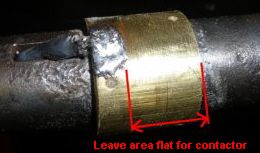

Finally started to work on the Horn. Started to clean up the brass bushing on the steering shaft by sanding it. After a few strokes I took a better look at it and found that the brass bushing around the insulator bushing was missing. Totally gone with just the insulator bushing left. Checked to make sure it had not slipped down towards the steering gear box and nothing. So I ordered up a new brass bushing with insulator from Ron. Got it a couple of days later and went to slide it down the shaft. Found it was too tight to even drive on. So I reamed it out until it would slide on. I then took the brass off the insulator and tinned the brass for the future solder job. Got the bushing in place and poked a wire up from the bottom hole just above the bushing. I tied the horn button wire onto it and pulled the wire back down the hollow shaft and out through the hole. I slipped a piece of heat shrink tube over the wire for added insulation where it goes through the hole. I then stripped the wire and tinned it with solder. Using a big soldering iron I heated everything up, flowing the solder together from the wire to the bushing. I managed to do all this without taking the steering box off or pulling the shaft out of the box.

This is the most finicky of jobs. You have to be careful to not melt the insulator when you solder the wire to the bushing. Too much heat and you start over.

Always clean the top of the steering shaft very well with sand paper for good electrical contact between the bronze cup and the hollow shaft. After testing everything works. Iím glad this job is behind me.Pulling new wire in Wire soldered to bushing

New Contactor

New Horn Button